Putting WaterSmart™ to Work For You

Traditional dyeing treats every step as a separate process, which means each step takes time, water and power.

WaterSmart™ additives are specially formulated to work together so all dye steps can be done at the same time in the same water. Each component in WaterSmart™ not only acts to do its job but also takes care of keeping impurities away from the fabric. This is the secret behind the technology.

Up to 3 hours saved on each batch

Traditional

NICCA

Traditional Cycle

7.5 hours | 48-80 liters per kg of fabric

Scour

soap

Rinse

water

Rinse

water

1.5 Hours

Dye

standard chemistry & disperse dyes

Reductive Clear

caustic & hydrosulfite

4.5 Hours

Neutral

H2O2

Rinse

acid

Rinse

water

1.5 Hours

NICCA WaterSmart™ Cycle

4.5 hours | 12-20 liters per kg of fabric

Dye

Scour In-Bath: Sunmorl scour,

Neocrystal chelating agent,

Sunsolt disperse/leveler, and disperse dyes

Reductive Clear

Sunmorl wash,

adjust to 3.5-4.5 pH

3.5 Hours

Rinse

water

Rinse

darks option

1 Hour

Frequently Asked Questions

Quality is improved using the WaterSmartTM system. Dye problems such as spots are virtually eliminated resulting in less rework.

Although the per pound cost may be higher, usage is generally lower, rework is less and other savings will more than cover your chemicals costs.

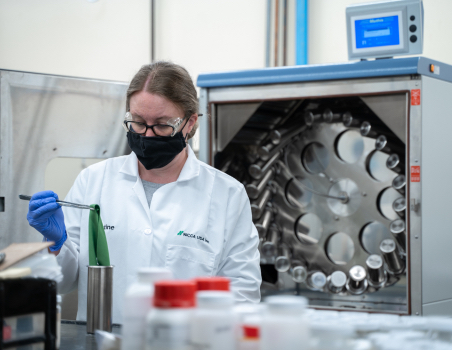

NICCA is a global company with facilities and distributors worldwide.

No. WaterSmartTM has no effect on the shade.

NICCA is well known as a solution provider and will work with you to develop and optimize your process, tweak formulas, and even custom develop if necessary.

Reduced Water Usage

With WaterSmart™ inside, you will reduce your water usage up to 75%. That’s great for business and good for the planet.

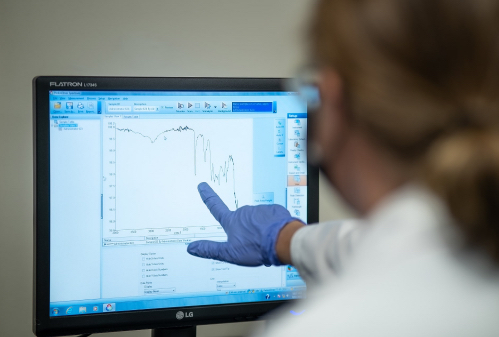

Technology in WaterSmart™ products keep you dye bath water clean. They do this in a number of ways:

- by keeping impurities way from the fabric and away from equipment

- by perfectly dispersing themselves and dyestuff into the bath

- by working together, not competing, to complete the dye process in the same water

Reduced Cycle Time

Make time stand still. Your cycle time will be reduced by 40%. What are you going to do with all your new-found time? Make more product of course.

Dyeing fabric is a very involved process. Scour, rinse and rinse again. Then dye, clear the process, adjust the pH and rinse again – twice. Add in complications like dye spots, machine cleaning and oligomer and it can be difficult to meet demand.

- The ability to scour and dye fabric in the same bath, without the need for pH adjustment after dyeing, eliminates four steps and three hours from a seven and a half hour dye process. That is a lot!

- Consider that time includes both machine and labor and you can imagine that what used to be made in a 12 hour shift can now be made in 8 hours.

- WaterSmart™ also reduces oligomer, dye spots and machine cleaning. Even more time!

Reduced Costs

Why is WaterSmart™ so “smart”? How does more than enough savings to pay for your chemicals sound?

The water and energy savings alone will pay for chemicals costs. But there are other savings:

- WaterSmart™ also reduces wastewater and associated costs

- Spots and other dye problems are reduced so rework is less with WaterSmart™

- Reduced oligomer and machine cleaning costs

Related Links

TBD

TBD